Welcome to BelMag

BelMag is one of the leading Russian auto parts makers for domestic and foreign car brands.

Located in a city with a unique history and location, Magnitogorsk, BelMag is a part of a thriving industrial community and has become an important part of

the metallurgical capital of Russia.

Today BelMag is a leading research and development center.

Read moreTechnology

Reference Projects

Supply to OEM is the most valuable and evident recognition of BelMag production quality.

Constant improvement and renovation of the test and manufacturing equipment set-up allows implementing scientific and technological potential of the company to the full extent.

Therefore the natural result of it is product manufacture, the quality of which was greatly appreciated by millions of car drivers throughout the country.

Scientific approach and competence in design and auto parts manufacture provided the company more than 15 year experience in manufacturing and supplying products.

Blank Production

Blank production as a basis for technological process.

One of the main conditions of manufactured product quality is the quality of its components.

The structure of the company includes a blank production complex with the high level of automatic processes so that performance time and work input can be optimized.

Provision of the company allows implementing the cold and hot forging processes (stamping and die forging) with subsequent heat treatment and 100% blank quality control.

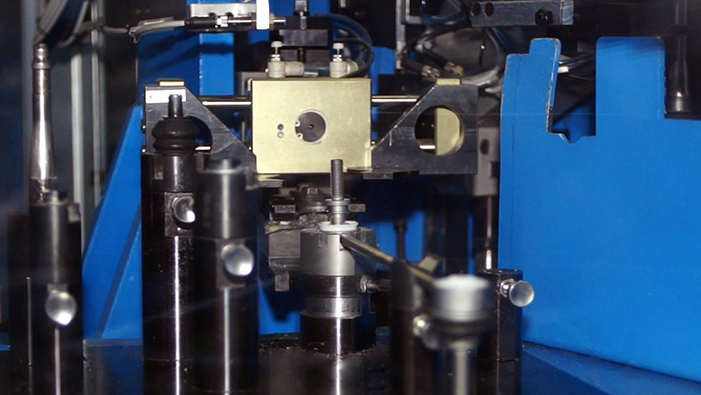

Machining

BelMag machining has all necessary equipment for ball joint components manufacturing.

Machining processes represent one of the main core competencies of BelMag. High level of productivity and automation of technological process allows machining operation of components immediate in the enterprise.

Extensive fleet of technological equipment for machining operation provides implementation of the whole operational range:

- Ball stud neck forming;

- Ball stud neck turning;

- Ball stud threading;

- Ball stud sphere machining;

- Ball stud final machining;

- Ball joint housing machining.

All the machining processes for components involve 100% quality control.

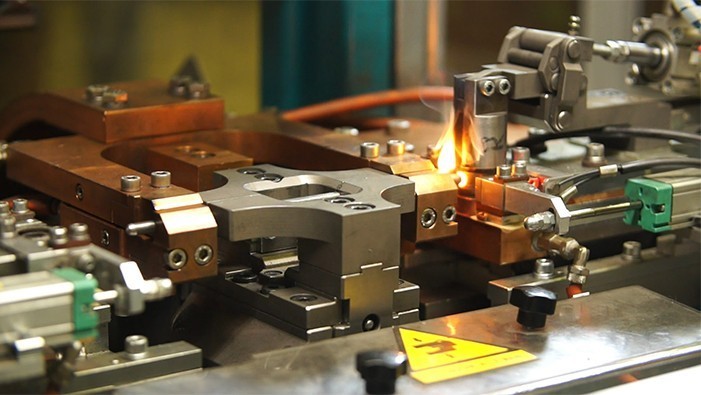

Welding

BelMag has a complex of automated welding equipment.

Enhancing constant technological re-equipment BelMag acquired welding equipment providing 100% quality control made by leading global manufacturers.

Apart from productivity and automation high levels BelMag welding equipment records all technological parameters of weldments and keeps the information in the special database permanently. It allows to organize an absolute identification and traceability of all the products manufactured on the equipment.

Assembling

BelMag unique assembling equipment set-up has no analogues in Russia.

The process of ball joint assembling is produced on technological equipment produced exclusively for BelMag by world leader in design and specialized technological equipment manufacture.

The equipment allows producing complete assembly cycle of ball joint includes, ultrasonic welding of a finished product and ensures compliance with parameters during an assembly process.

All parameters of a technological process are recorded and kept in a separate database providing complete identification and product traceability.

Engineering

R&D / Design Processes

To produce truly high-quality product is to design a product.

Designing new products BelMag research and development department puts an emphasis on each component, specifically, not only on the shape, but also on the material of a product as well as technologies used in manufacture.

BelMag works closely with the leading specialists of Nosov Magnitogorsk and Bauman Moscow state technical universities, therefore scientific activity of the company is more than successful and still has all prospects for prosperity.

One of the results of scientific approach in auto parts developing and designing is a range of patents and inventions, practical value

of which is traced on different stages of company development.

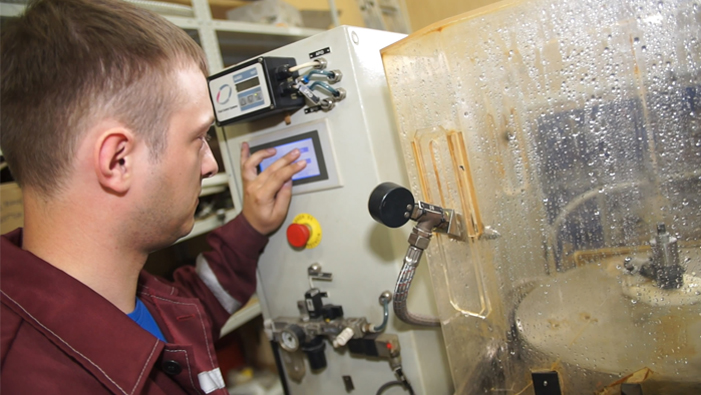

Testing

BelMag has in-house validation center that has no analogues in Russia.

Laboratories of the company are fitted with equipment produced by leading global manufacturers as well as equipment manufactured

in-house by BelMag specialists.

Durability and wear tests are performed according to domestic and foreign car manufacturers’ requirements. Such tests fully simulate climatic conditions (heat, cold, water, road dust etc.).

The results of these tests are so realistic that it allows to avoid expensive and time-consuming road tests.

Cooperation With Universities

BelMag scientific activity is an essential part of the company's life.

Since the time the company was founded it works closely with Nosov Magnitogorsk and Bauman Moscow state technical universities.

Most of engineering specialists in BelMag are graduates of these universities.

In 2001 in Nosov Magnitogorsk state technical university the Department of technology, certification and car service was opened, the head of which was Doctor of Technical Science, professor and today BelMag CEO — Igor Gun.

With the lead of BelMag CEO, Igor Gun, and in cooperation with university researchers scientific direction in the field of research and improvement of suspension and steering parts manufacturing process successfully operates.

One of the outcomes of such cooperation is 1 Doctor of Technical Science and 8 Candidates of Technical Science working in BelMag.