Blank Production

Blank production as a basis for technological process.

One of the main conditions of manufactured product quality is the quality of its components.

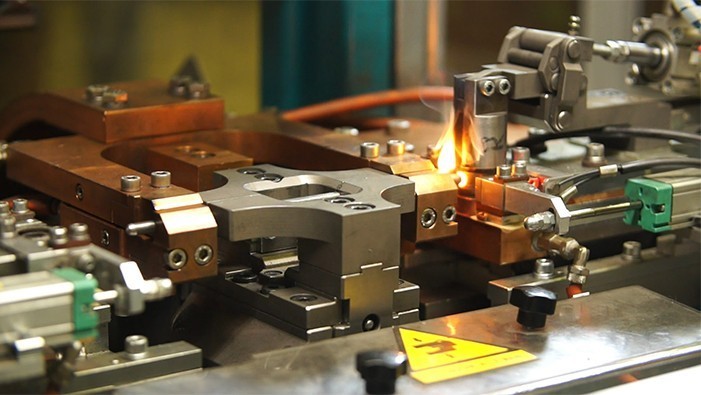

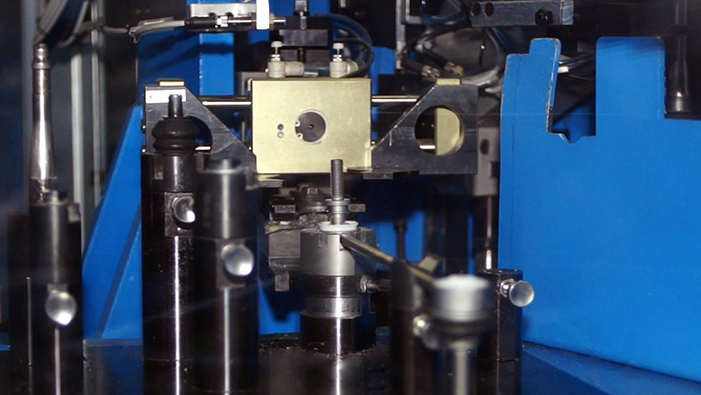

The structure of the company includes a blank production complex with the high level of automatic processes so that performance time and work input can be optimized.

Provision of the company allows implementing the cold and hot forging processes (stamping and die forging) with subsequent heat treatment and 100% blank quality control.

Next article